Loading...

{{ error }}

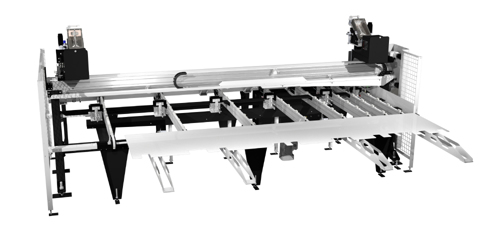

SB 3011 - PVC Profile Processing and Cutting Center

Hadımköy Atatürk Sanayi Bölgesi, Ömerli Mahallesi, 75.Yıl Caddesi, Uzunçayır Sokak, No:12, P.K. 34555 Arnavutköy İstanbul

Highlights

- 8-axis machining center

- Sturdy mechanical structure suitable for high-speed operation

- Profile feeding capacity of 8 units

- Profile processing length of 6500 mm

- Machinable profile section dimension of 130 x 210 mm

- 2 x Ø 500 mm saw

- Ø 420 mm saw

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Mitsubishi PLC control system

- Remote service support

- Automatic profile recognition system

- Automatic lubrication system

Design

- Mechanical structure capable of processing PVC profiles at high speed and with high quality

- Cast and welded parts with stress relief applied to ensure precision at consistently high speeds

- Capability to perform operations such as channel cutting, drilling, marking, and cutting at various angles

- Automatic lubrication system

Control Panel

- Versatile adjustable, ergonomic kiosk

- 17'' screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- High performance PLC control system

- Compatibility with 3rd party software

- Data transfer via USB and COM Port

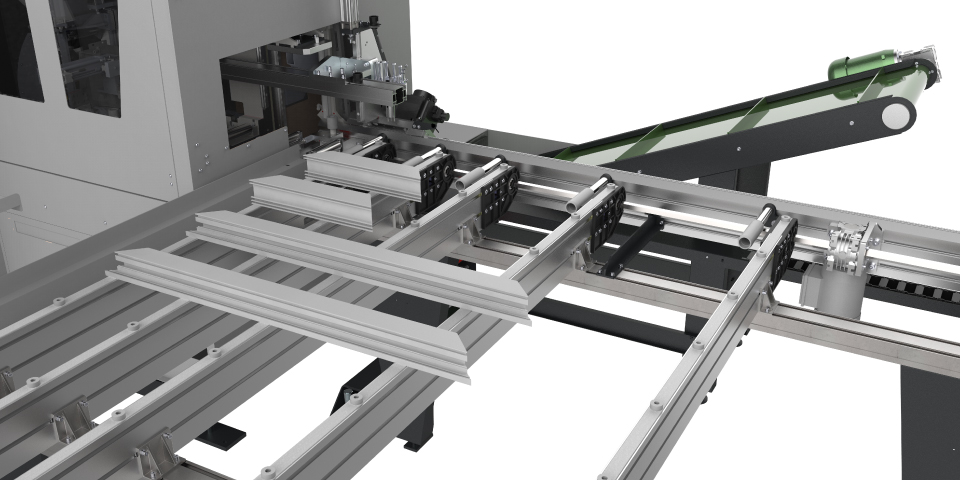

Input Unit

- Servo controlled profile driving robot

- Strong profile holding structure

- Conveyor system that can carry up to 9 profiles

- Profile transport with a maximum length of 6500 mm and a minimum length of 886 mm

- Automatic profile recognition system

- Linear measuring system

- Infinite length machining option

Processing Unit

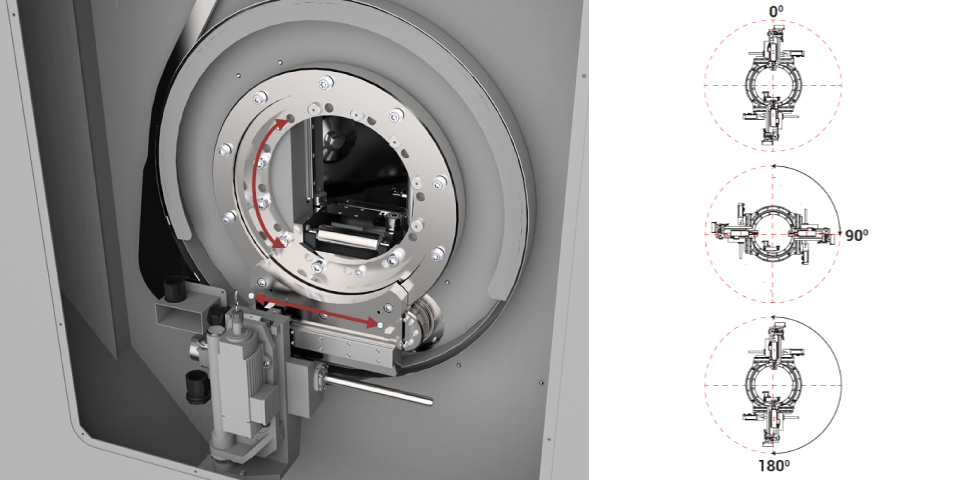

- Two 3-axis, servo-controlled units

- The ability of two milling cutters working simultaneously with high precision

- Capability to machine barrel slots on both sides simultaneously

- 360° linear operation around the profile

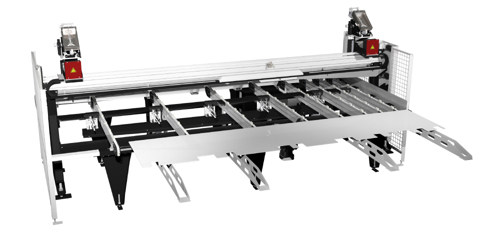

Cutting Unit

- Servo controlled saw feed speed

- 2 x Ø 500 mm saws (±45°)

- Ø 420 mm saw (90°)

Exit Unit

- Servo controlled exit robot

- Profile length up to 4000 mm

- Conveyor for automatic transfer of cut parts

- Barcode printer

- Chip conveyor for waste parts

Safety

- Ability to resume operation from the point of interruption with the UPS system

- Automatic recovery function that moves the spindle to a safe area

- Safety label

Technical Support

- Periodic maintenance reminder function

- Remote service support

Technicial Specifications

| Input Group | Conveyor | Axis Speed | 8,8 | m/min | ||

| Profile Holder | Axis Speed | 275 | m/min | |||

| Profile Holder | Part Machining Length | 6500 | mm | |||

| Processing Unit | Tool | Motor Power | 2 x 0,75 | kW | ||

| Tool | Maximum Rotation Speed | 18000 | cycle/min | |||

| Y1-Y2 Axis | Motor Power | 0,4 | kW | |||

| Y1-Y2 Axis | Axis Speed | 22,5 | m/min | |||

| Z1-Z2 Axis | Motor Power | 0,4 | kW | |||

| Z1-Z2 Axis | Axis Speed | 22,5 | m/min | |||

| B Axis | Motor Power | 0,75 | kW | |||

| B Axis | Axis Speed | 128 | m/min | |||

| B Axis | Angle | 0° / 180° | ° | |||

| Cutting Unit | Saw 1 (0°) | Motor Power | 1,5 | kW | ||

| Saw 1 (0°) | Maximum Rotation Speed | 2800 | cycle/min | |||

| Saw 1 (0°) | Saw Diameter | 420 | mm | |||

| Saw 2 (+45°) | Motor Power | 1,5 | kW | |||

| Saw 2 (+45°) | Maximum Rotation Speed | 2800 | cycle/min | |||

| Saw 2 (+45°) | Saw Diameter | 500 | mm | |||

| Saw 3 (-45°) | Motor Power | 1,5 | kW | |||

| Saw 3 (-45°) | Maximum Rotation Speed | 2800 | cycle/min | |||

| Saw 3 (-45°) | Saw Diameter | 500 | mm | |||

| Z Axis | Motor Power | 0,75 | kW | |||

| Z Axis | Axis Speed | 22,5 | m/min | |||

| Output Group | Conveyor | Axis Speed | 8,8 | m/min | ||

| Profile Holder | Axis Speed | 275 | m/min | |||

| X Axis | Motor power | 1,5 | kW | |||

| X Axis | Axis Speed | 300 | m/min | |||

| Chip Conveyor | Motor power | 0,37 | kW | |||

| Machine Dimensions | Profile Holder | Pressure | 6-8 | bar | ||

| Air | Consumption | 250 | Lt/min | |||

| Profile Holder | Voltage | 220/230/400 | V | |||

| Profile Holder | Power | 13,5/13,5/13,5 | kW | |||

| Profile Holder | Net Machine Weight | 3508 | kg | |||

| Profile Holder | Gross Weight | 4162 | kg | |||

| Profile Holder | Sound | 96 | d(b) | |||

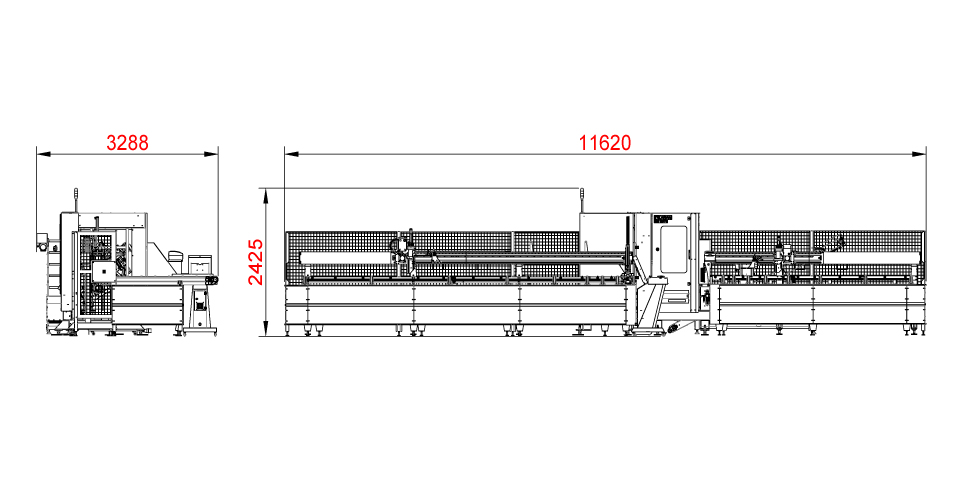

| Profile Holder | Length(L) | 11620 | mm | |||

| Profile Holder | Width(W) | 3288 | mm | |||

| Profile Holder | Height(H) | 2425 | mm | |||

- Multi-compartment cart that supports workflow optimization

- Servo-controlled dual-station unit

- Fast and automatic screws for profiles with support plates at desired intervals

- Servo-controlled dual-station unit

- Fast and automatic screws for profiles with support plates at desired intervals

- Drilling capability for profiles with support plates at desired intervals