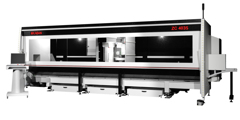

- Axis velocities whose average exceed 100 m/min

- Profiling length 7630 mm

- Double station profiling length 3615 mm x 2

- Machinable profile section size 450 x 300 mm

- Number of clamps is 10

- Spindle motor 11-13.5 kW 24,000 rpm

- The number of magazine sets is 12 pieces

- Ø 400 mm saw

- Mitsubishi CNC control unit

- Automatic tool length measuring

- Automatic positioning vices

- Automatic tool recovery in case of power failure

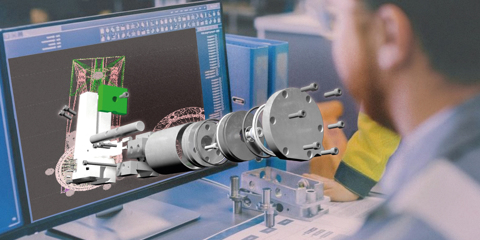

Design

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Axis velocities whose average exceed 100 m/min

- Milling, notching, drilling, threading, countersinking, cutting, etc. ability

- Machining length in single station operation 7630 mm

- Machining length in double station operation 3615 mm x 2

- Machinable profile section size 450 x 300 mm

- Coolant spray system

Control Panel

- 19'' screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Compatibility with .NCX extension software

- High performance 4+1 axis Mitsubishi CNC control unit

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

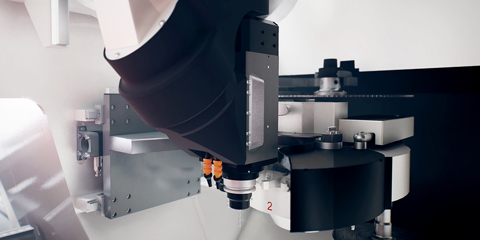

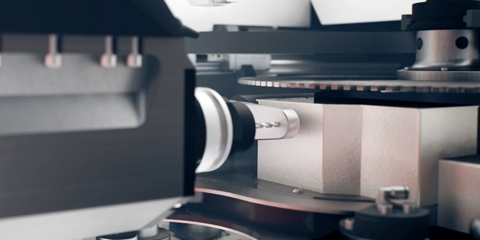

Spindle

- Liquid cooled 8.5 kW 24,000 rpm spindle with thermostat sensor

- Tool cooling system with oil-air mixture spray speed adjustment, liquid level sensor

- Tool holder and tool holder cleaning system

- Tool change safety protocols written to minimize operator errors as much as possible

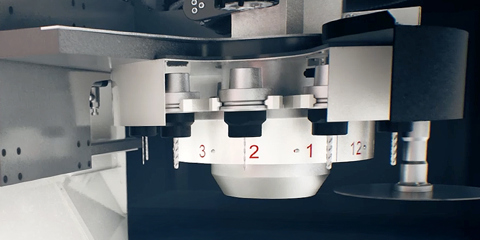

Magazine

- Tool change feature in maximum 4 seconds.

- It saves time by changing tools while moving from operation to operation on the part.

- Ø200mm saw can be mounted.

Saw Magazine

- Tool change feature in maximum 8 seconds

- Easy design for saw replacement

- Saws up to maximum Ø400mm can be installed

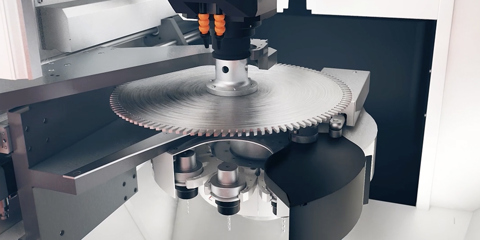

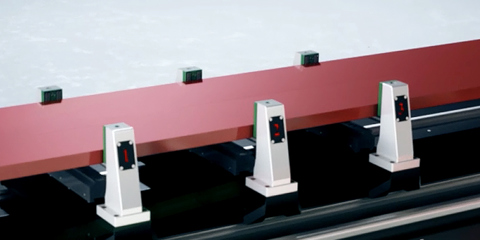

Profile Supports

- Suitable for working with long profiles

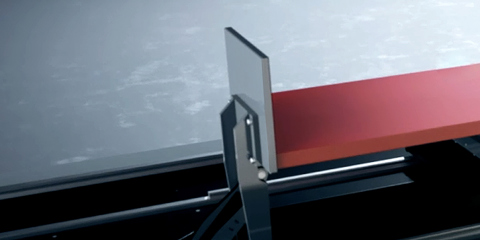

Vices

- There are 10 clamps as standard. The number of clamps can be increased as an option

- Since the surfaces on which the profile sits are roller system, it provides profile sliding comfort on the clamp surface

- According to the prescriptions on the workpiece, the clamps take servo-controlled automatic position

- Easy part resetting with double-sided profile resting system

- It offers the possibility to process profiles in long lengths. Ø400 mm saw can be used for notching the ends of the profiles

- Thanks to the pressure regulator, the clamp tightness can be adjusted according to the profile thickness

- Parts smaller than 300mm can be held and cut with a single clamp

- Thanks to the profile transport system with vice, the saw can easily enter between the profiles

Safety

- Auto-recovery function that sends the spindle to the safe zone

- Operational safety with protective fences and safety barriers

- Security labels

|

Description

|

|||||||

| 5 Axis Group | X Axis | Motor power | 3,5 | kW | |||

| X Axis | Axis Speed | 140 | m/min | ||||

| X Axis | Machining Length | 7630 | mm | ||||

| Y Axis | Motor power | 1,5 | kW | ||||

| Y Axis | Axis Speed | 80 | m/min | ||||

| Y Axis | Machining Length | 460 | mm | ||||

| Z Axis | Motor power | 1,5 | kW | ||||

| Z Axis | Axis Speed | 40 | mm | ||||

| Z Axis | Machining Length | 300 | mm | ||||

| A Axis | Motor power | 0,5 | kW | ||||

| A Axis | Axis Speed | 255 | º/sec | ||||

| A Axis | Angle | ±90 | º | ||||

| C Axis | Motor power | 0,5 | kW | ||||

| C Axis | Axis Speed | 255 | º/sec | ||||

| C Axis | Angle | ±180 | º | ||||

| Part Machining | Spindle | Motor power | 8,5 | kW | |||

| Spindle | Rotation Speed | 24000 | cycle/min | ||||

| Tool Warehouse | Tool magazine | Tool Number | 12 | Piece | |||

| Saw | Diameter | 200 | mm | ||||

| Saw | Diameter | 400 | mm | ||||

| Part Handling and Holding | Clamp | Axis Speed | 15 | m/min | |||

| Clamp | Number of Clamps | 10 | Piece | ||||

| Technicial Specifications | Air | Pressure | 6-8 | Bar | |||

| Air | Total Air Consumption | 256 | l/min | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Power | 16,75 | kW | ||||

| Feed | Current | 42 | A | ||||

| Weight | Net | 10435 | kg | ||||

| Weight | Gross | 10600 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 11515 | mm | ||||

| Machine Dimensions | Width | 3894 | mm | ||||

| Machine Dimensions | Height | 2547 | mm | ||||