- Planned Production Capacity with Standard Processing Time of the System

- High-Speed, Maximum-Quality Operation

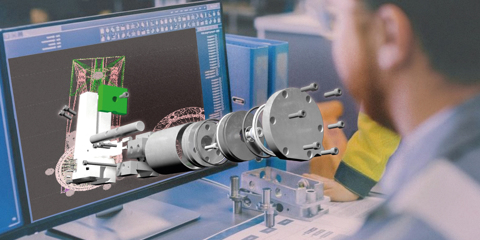

Design

- It automates the corner welding and corner cleaning processes of PVC profiles of different types and sizes simultaneously by integrating CNC operation.

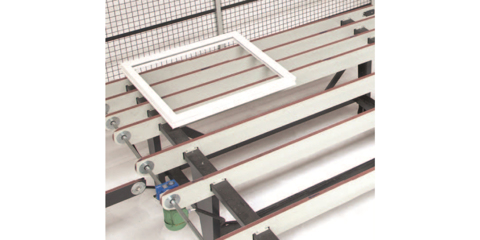

- Robot rotates frames to their appropriate positions, minimizing time losses during frame rotation.

- With wireless info transfer between units, all units work synchronously with each other, time losses are minimized.

- With automation, standard processing time, high production accuracy and maximum cost efficiency are achieved.

- It saves working space and labor by producing more than the capacity of four welding and cleaning lines.

- A frame is produced on average every 20-28 seconds.

- It saves space compared to traditional machines used for similar production quantity.

Technical Support

- Automatic lubrication system is available.

- Fast technical support service is provided by remote connection.

Control Panel

- It works compatible with all joinery and optimization programs thanks to its easy-to-use and flexible operating system.

- Thanks to the special software, the stacking layout of the profile trolley can be selected from the screen and production can be made on a customer basis.

- The parameters of all units can be easily adjusted independently of each other.

Source

- It can be welded by entering a manual measurement without using a barcode reader.

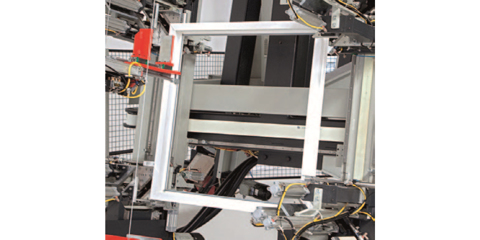

- 4 pieces of 4 welding machines on the rotating body are welded simultaneously.

- The machine continues to weld during rotation.

- While first unit is ascending, the robot takes the welded frame from fourth unit.

- Welds four corners of PVC profiles at the same time at an angle of 90°.

- Saves time and cost thanks to the teflon renewal system in the form of rolls.

- Long-lasting heater plate distributes heat uniformly.

- It provides measurement stability thanks to its linear measurement system.

- Time is saved thanks to the practical welding mold replacement system.

Transfer Robot

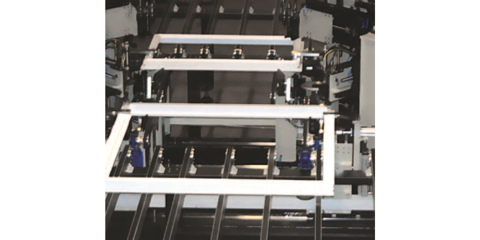

Cleaning

- It cleans the welding chips of the frames with high speed and quality with 18 servo motors.

- Frames that have finished cleaning are waiting in the output unit.

Exit Unit

Production Capacity

- Production capacity can be planned due to the fact that the processing time of the system is standard.

|

Description

|

|||||||

| Cross-Section Dimension of the Cleanable Profile | Max. Profile Size | 170 x 225 | 170 x 225 | ||||

| Min. Profile Size | __ x 30 | __ x 30 | |||||

| Cleanable Frame Size | Max. Frame Size | __ x 2.500 | __ x 2.500 | ||||

| Min. Frame Size | __ x 400 | __ x 400 | |||||

| Weldable Profile Cross-Section Dimension | Max. Cross-Section Measurement | 130 x 190 | 130 x 190 | ||||

| Min. Cross-Section Measurement | __ x 40 | mm | |||||

| Weldable Frame Size | Max. Frame Size | 2.355 x 2.820 | 2.355 x 2.820 | ||||

| Min. Frame Size | 450 x 450 | 450 x 450 | |||||

| Saw | Motor Speed | 6000 | 6000 | ||||

| Diameter | 250 | 250 | |||||

| Welding | Angle | 90 | 90 | ||||

| Air | Pressure | 6-8 | 6~8 | ||||

| Consumption | 696 | 696 | |||||

| Feed | Voltage | 400 | 400 | ||||

| Power | 65,87 | 65,87 | |||||

| Current | 131,74 | 131,74 | |||||

| Weight | Net Machine Weight | 23950 | 20860 | ||||

| Gross Weight | 27670 | 24110 | |||||

| Sound | Sound | 96 | 96 | ||||

| Machine Dimensions | Length(L) | 23860 | 24000 | ||||

| Width(W) | 10944 | 9000 | |||||

| Height(H) | 4075 | 4000 | |||||