- Triple drilling and espagnolette hole opening on sash frames

- Automatic Screwing and Feeding Unit

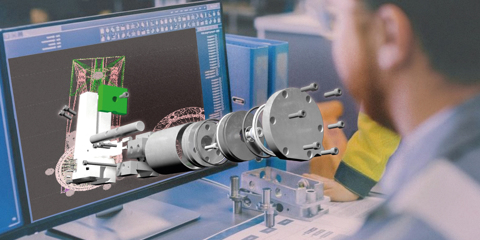

Design

- Single opening espagnolette on door sashes can be mounted.

- Triple drilling and espagnolette hole opening on sash frames.

- Drills hinge and pin holes on right and left sashes.

- Automatic centering system to center

different profile brands and series.

- Triple drilling and espagnolette hole

opening on sash frames.

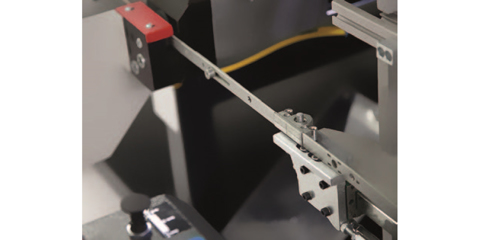

- Punch unit and practical measurement

system.

Automatic Centering System

- Opens triple arm holes and espagnolette channel in the wing frame.

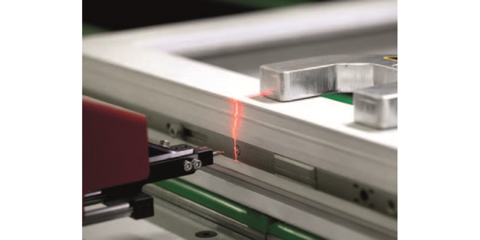

Automatic Screwing

- It makes screwing process easily with its linear laser unit.

|

Description

|

|||||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Total Air Consumption | 140 | l/min | ||||

| Feeding | Voltage | 400 | V | ||||

| Feeding | Force | 1,1 | kW | ||||

| Weight | Net | 864 | kg | ||||

| Weight | Gross | 1206 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 3513 | mm | ||||

| Machine Dimensions | Width | 2141 | mm | ||||

| Machine Dimensions | Height | 1911 | mm | ||||

| Machine Features | Frame processing dimensions | Maximum | 2500 / 2500 | mm | |||

| Available Screw Sizes | Screw Diameter | 3,5/4,2 | mm | ||||

| Available Screw Sizes | Countersink Diameter | 6,3 / 8,1 | mm | ||||

| Available Screw Sizes | Length | 15 / 40 | mm | ||||

| Triple Drilling | Engine Power | 1,1 | kW | ||||

| Triple Drilling | Rotation Speed | 925 | rpm | ||||

| Milling | Engine Power | 0,55 | kW | ||||

| Air Engine | Rotation Speed | 1500 | rpm | ||||

| Punch | Cutting Force | 3,7 | Ton | ||||

| Triple Drilling | Drill Diameter | 11/13 | mm | ||||

| Milling | Rotation Speed | 18 000 | rpm | ||||