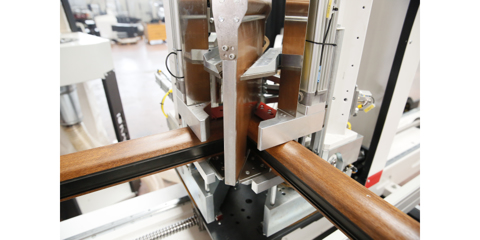

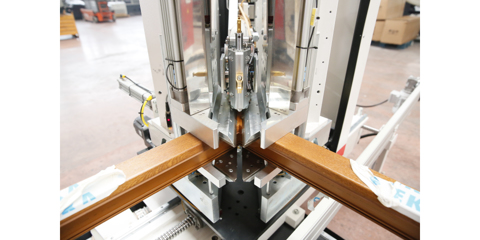

- Deburring-free welding of white and colored profiles

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Remote service support

- Automatic lubrication system

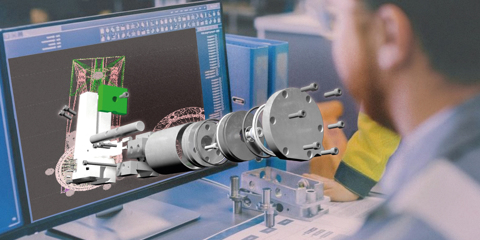

Design

- Cast and welded parts with stress-relief treatment to ensure precision at continuos high speeds

- Sliding Teflon replacement system on the resistance

- Easy profile feeding

- Smaller footprint compared to existing welding and cleaning centers

- Chip extraction system

- Pressure control system

Control Panel

- 19" screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Software enabling customer-specific production

- Mitsubishi PLC control system

- Adjustable heating via PID system based on profile type

- Adjustable heating and bonding time based on profile type

- Ability to define separate processes at each point on the profile drawing in DXF format

- Compatibility with third-party software

- Barcode reader integration

- Data transfer via USB and Ethernet connections

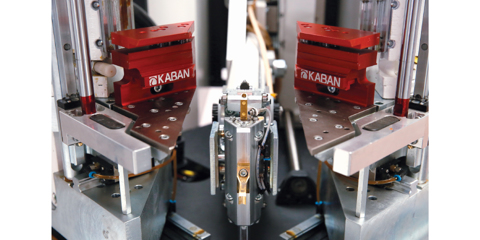

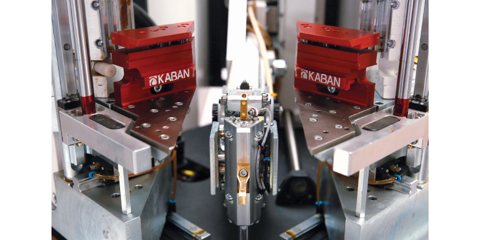

Welding Unit

- Easily changeable welding molds

- Easy profile feeding flow

- Top and internal profile clamping

- Milling group that adjusts profile lengths to the welding measurement, including gaskets

- Welding profiles at a 90° angle

- Cutting tools for removing burrs formed during welding

- Detailed adjustment capability with the cabin interface

Cutter

- With the chip collection system, the burrs formed in the milling process are vacuumed and accumulated in the chamber.

Heater Plate

Stripping Blade

|

Description

|

|||||||

| Welding Measures | Max. Cross-Sectional Size | mm | 200 | 140 x 190 | |||

| Width / Length | Maximum | 4100 / 2400 | mm | ||||

| Width / Length | Minimum | 500 / 500 | mm | ||||

| Welding | Angle | 90 | ° | ||||

| Machine Axes | Min. Cross-Sectional Size | mm | 1 | __ x 20 | |||

| Maximum Rotation Speed | cycle/min | 2 x 0,75 | 3000 | ||||

| Conveyor | Motor power | 2 x 0,37 | kW | ||||

| Welding Units x 4 | X Axis | Motor power | 0,4 | kW | |||

| Y Axis | Motor power | 2 x 0,75 | kW | ||||

| Z Axis | Motor power | 0,4 | kW | ||||

| Milling | Motor power | 0,75 | kW | ||||

| Milling | Rotation Speed | 10000 | rpm | ||||

| Resistance | Power | 2 | kW | ||||

| Technicial Specifications | Chip Absorber | Motor power | 3 | kW | |||

| Air | Pressure | 6-8 | bar | ||||

| Air | Total Air Consumption | 800 | l/min | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Power | 27 | kW | ||||

| Weight | Net | 4805 | kg | ||||

| Weight | Gross | 5477 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 8038 | mm | ||||

| Machine Dimensions | Width | 6437 | mm | ||||

| Machine Dimensions | Height | 2317 | mm | ||||