- Robust mechanical structure suitable for high speed

- Mitsubishi PLC control system

- User-friendly Kaban interface with easily adjustable parametric structure

- Working with barcode reader

- Ease of profile feeding

- Heat adjustable according to profile type with PID system

- Heating and welding time adjustable according to profile type

- Easy change of welding molds

- Tolerance system

- Cooling conveyor transporting the frame to the robot after the welding machine

- Robot moving the frame from the cooling table to the CNC corner cleaning machine

- Cleaning the four corners by automatically turning the frame

- Cleaning the welding chips on the lower and upper surfaces with stripping blades

- Cleaning of chips inside, including sill frames

- Cleaning the chips outside with a saw

- Cleaning of laminated profiles

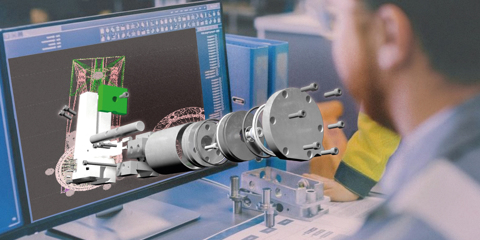

Design

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Welding and cleaning the four corners of the frames

- Teflon replacement system with sliding on the resistance

- Ease of profile feeding

- Working with barcode reader

- Pressure control system

Control Panel

- User-friendly Kaban interface with easily adjustable parametric structure

- Software that enables customer-based production

- Mitsubishi PLC control system

- Heat adjustable according to profile type with PID system

- Heating and welding time adjustable according to profile type

- Compatibility with 3rd party software

- Working with barcode reader

- Data transfer via memory card

- Memorize 2,000 profile information

- Ethernet connection

Welding Unit

- Easy change of welding molds

- Easy profile feed flow

- Top clamps

- Tolerance system

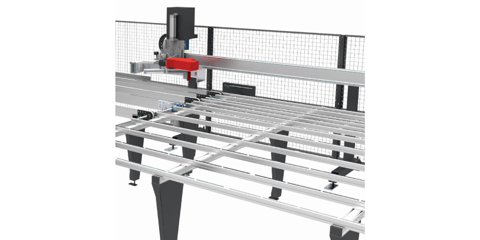

Transfer Systems

- Robot moving the frame from the cooling table to the CNC corner cleaning machine

- Rotation speeds from 1s to 4s proportional to the frame size

- Cleaning the four corners by automatically turning the frame

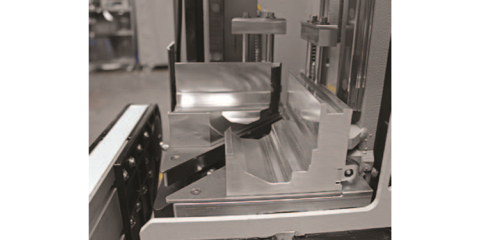

Cleaning

- Cleaning the welding chips on the lower and upper surfaces with stripping blades

- Cleaning of chips inside including sill frames

- Cleaning the chips outside with a saw

- Cleaning of laminated profiles

- Manual feeding possibility

|

Description

|

|||||||

| Welding Measures | Profile | Height | 210 | mm | |||

| Profile | Width | 130 | mm | ||||

| Width / Length | Maximum | 2560 / 3575 | mm | ||||

| Width / Length | Minimum | 325 / 410 | mm | ||||

| Angle | Welding | 90 | ° | ||||

| Welding Machine Axes | X Axis | Motor power | 0,75 | kW | |||

| Y Axis | Motor power | 2 x 0,4 | kW | ||||

| Conveyor | Motor power | 2 x 0,37 | kW | ||||

| Cooling Unit | Conveyor | Motor power | 0,55 | kW | |||

| Conveying and Turning Unit | X Axis | Motor power | 1,5 | kW | |||

| A Axis | Motor power | 0,75 | kW | ||||

| Corner Cleaning | X Axis | Motor power | 0,75 | kW | |||

| Z Axis | Motor power | 0,75 | kW | ||||

| Saw | Motor power | 0,55 | kW | ||||

| Saw | Rotation Speed | 6000 | rpm | ||||

| Saw | Diameter | 230 | mm | ||||

| Milling | Motor power | 2 x 0,55 | kW | ||||

| Milling | Rotation Speed | 18000 | rpm | ||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Total Air Consumption | 180 | l/min | ||||

| Feed | Voltage | 230 (Köşe Tem.) /400 (Kaynak) | V | ||||

| Feed | Power | 16,45 | kW | ||||

| Weight | Net | 3760 | kg | ||||

| Weight | Gross | 4537 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 14279 | mm | ||||

| Machine Dimensions | Width | 5940 | mm | ||||

| Machine Dimensions | Height | 2154 | mm | ||||