- Ø 420 mm saw

- Profile fixing pistons

- Safety covers

- 7'' touch screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Compatibility with 3rd party software

- Mitsubishi PLC control system

- Automatic slicing system

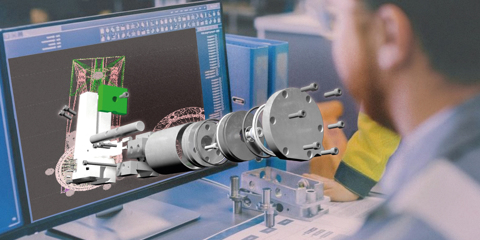

Design

- Cast and welded parts with stress relief applied to ensure precision at consistently high speeds

- Profile clamping pistons

- Left-side profile support table

- Safety covers

- Ability to operate with a single head

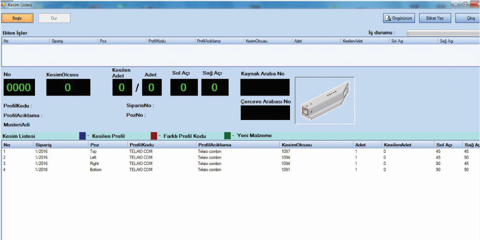

Control Panel

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Compatibility with 3rd party software

- Mitsubishi PLC control system

- Automatic slicing system

- Data transfer via memory card

- Memorizes 1250 different cutting sizes

- Ethernet connection

|

Description

|

|||||||

| Moving Head | X Axis | Motor power | 0,37 | kW | |||

| X Axis | Axis Speed | 13,7 | rpm | ||||

| Cut Length | Maximum | 90° | 4000 | mm | |||

| Minimum | 90° | 600 | mm | ||||

| Fix and Moving Head | Saw | Motor power | 1,5 | kW | |||

| Saw | Diameter | 420 | mm | ||||

| Cut | Angle | 45 - 90 | ° | ||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Total Air Consumption | 44 | l/min | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Power | 3,5 | kW | ||||

| Weight | Net | 1060 | kg | ||||

| Weight | Gross | 1185 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Height | 1516 | mm | ||||

| Machine Dimensions | Width | 1414 | mm | ||||

| Machine Dimensions | Length | 6914 | mm | ||||