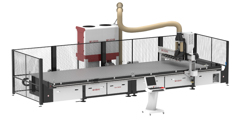

- Robust mechanical structure suitable for high speed

- Axis speeds whose averages exceed 110 m/d

- 8 pieces profile feeding capacity

- Profile machining length 7,500 mm x 600 mm

- Machinable profile section size 150 x 190 mm

- Ø 550 mm saw

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Mitsubishi PLC control system

- Service support with remote connection

- Automatic profile recognition system

- Coolant spray system

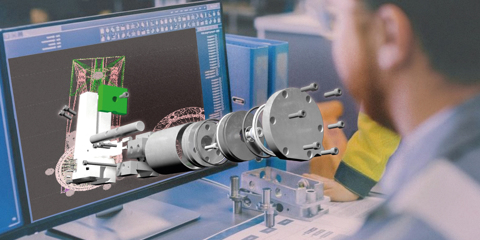

Design

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Fully automatic processing of a wide variety of doors, windows and similar profiles, including industrial products

- Suitable for grooving, drilling, marking, cutting at different angles, etc. ability to process

- Coolant spray system

Control Panel

- 19'' screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- High performance Mitsubishi PLC control system

- Compatibility with 3rd party softwares

- Data transfer via USB and COM Port

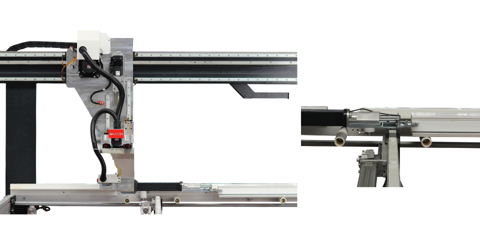

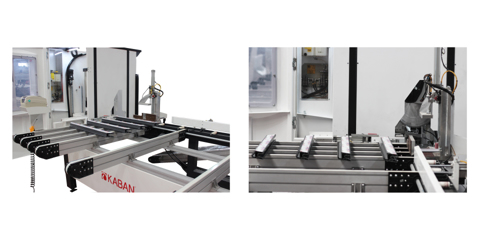

Input Unit

- Profile holder with ?? Nm torque control and high measurement accuracy with its flexible structure

- Conveyor system that can carry 8 profiles

- Profile transport up to 7500 mm, at least 600 mm long

- Automatic profile recognition system

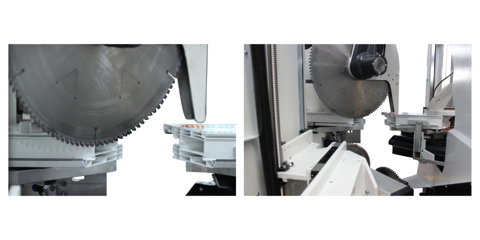

Cutting Unit

- Adjustable saw feed speed

- Ø 550 mm saw

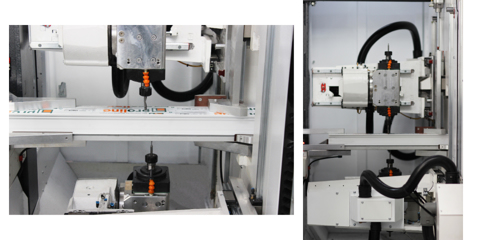

Processing Unit

- Machining group angles move 270°.

- Thanks to the reciprocal SERVO motors in the milling unit, it has the opportunity to perform double-sided operations.

Exit Conveyor and Chip Conveyor

- Conveyor where the cut pieces are transferred automatically

- Barcode printer

- Chip conveyor for waste parts

Safety

- Auto-recovery function that sends the spindle to the safe zone

|

Description

|

|||||||

| Input Group | Conveyor | Motor Power | 0,37 | kW | |||

| Conveyor | Axis Speed | 9 | m/min | ||||

| Robot | X Axis | Motor Power | 1,5 | kW | |||

| X Axis | Axis Speed | 145 | m/min | ||||

| X Axis | Machining Length | 7500 | mm | ||||

| Y Axis | Motor Power | 0,4 | kW | ||||

| Y Axis | Axis Speed | 90 | m/min | ||||

| Y Axis | Machining Length | 130 | mm | ||||

| Z Axis | Motor Power | 0,4 | kW | ||||

| Z Axis | Axis Speed | 90 | m/min | ||||

| Z Axis | Machining Length | 230 | mm | ||||

| Mill 1 / Mill 2 | Milling | Motor Power | 1,5 | kW | |||

| Milling | Max Rotation Speed | 12000 | cycle/min | ||||

| X Axis | Motor Power | 0,4 | kW | ||||

| X Axis | Axis Speed | 90 | cycle/min | ||||

| X Axis | Machining Length | 260 | mm | ||||

| Y Axis | Motor Power | 0,75 | kW | ||||

| Y Axis | Axis Speed | 90 | m/min | ||||

| Y Axis | Machining Length | 240 | mm | ||||

| Z Axis | Motor Power | 0,75 | kW | ||||

| Z Axis | Axis Speed | 90 | m/min | ||||

| Z Axis | Machining Length | 220 | mm | ||||

| A-Axis | Motor Power | 0,4 | kW | ||||

| A-Axis | Axis Speed | 326 | °/sec | ||||

| A-Axis | Angle | 0 - 270 | ° | ||||

| Cut | Saw | Motor Power | 2,2 | kW | |||

| Saw | Max Rotation Speed | 2850 | cycle/min | ||||

| Saw | Saw Diameter | Ø550 | mm | ||||

| Z Axis | Motor Power | 0,75 | kW | ||||

| Z Axis | Axis Speed | 90 | m/min | ||||

| Z Axis | Machining Length | Kesim Diyagramı | mm | ||||

| C Axis | Motor Power | 0,4 | kW | ||||

| C Axis | Axis Speed | 900 | º/sec | ||||

| C Axis | Angle | 30 - 150 | º | ||||

| Output Group | Conveyor | Chip Conveyor Motor | 0,37 | kW | |||

| Conveyor | Output Conveyor Motor | 0,37 | kW | ||||

| X Axis | Motor Power | 0,4 | kW | ||||

| X Axis | Axis Speed | 90 | m/min | ||||

| Technicial Specifications | Air | Pressure | 6 – 8 | bar | |||

| Air | Consumption | 300 | l/min | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Power | 14 | kW | ||||

| Weight | Net | 5010 | kg | ||||

| Weight | Gross | 5110 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 14825 | mm | ||||

| Machine Dimensions | Width | 3900 | mm | ||||

| Machine Dimensions | Height | 2571 | mm | ||||