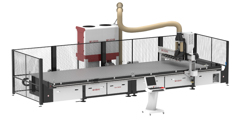

- Axis speeds averaging 80 m/d

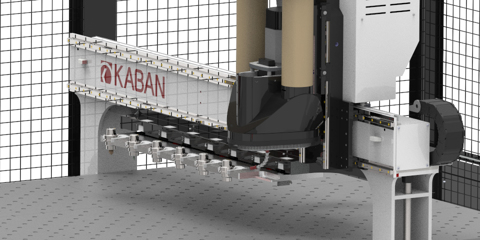

- Multi-compartment tray with vacuum holding and lifting

- Maximum machinable length width 4300 mm x 1600 mm

- Maximum machinable height 180 mm

- Spindle motor 7.5 kW 24,000 rpm

- Air spray system

- Number of magazine teams 6 pieces

- 19'' screen

- Mitsubishi PLC control unit

- Windows-based, user-friendly Kaban interface with easily adjustable parametric structure

- Ability to handle 2D and 3D geometries

- Optical communication and command boost

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

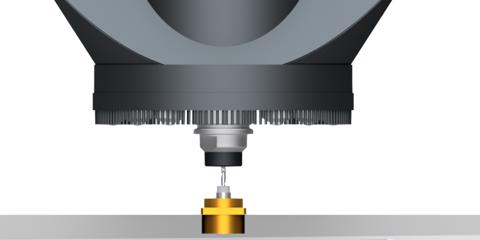

- Automatic tool length measurement

- Automatic tool change

- Automatic tool recovery in case of power failure

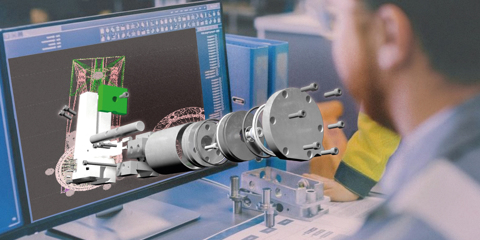

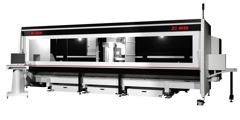

Design

- The machining time of the machine has been reduced to a minimum thanks to the axis speeds of october average of 80 m/min.

- It is widely used in construction, furniture, advertising, shipbuilding, energy, automotive and aviation industries.

- Products can be used on joints, cuts, holes, channels, etc. processing and sizing are carried out by operations.

- It is equipped with high-precision technological components.

Control Panel

- 19'' screen

- Windows-based, user-friendly Kaban interface with easily adjustable parametric structure

- Ability to handle 2D and 3D geometries

- High performance Mitsubishi PLC control unit

- Optical communication and command boost

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

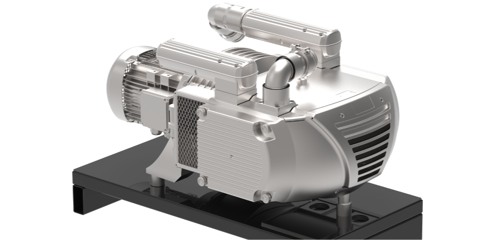

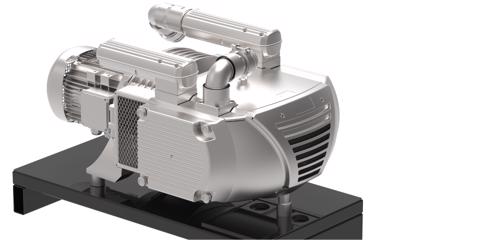

Vacuum System

- Automatic vacuum zone selection according to the workpiece size

- Reference pins for easy positioning of the workpiece

- Blowing system that allows the workpiece to move easily on the workbench

Safety

- Auto-recovery function that sends the tool to the safe zone

|

Description

|

|||||||

| ***? | ***? | ***? | 0,75 x 2 | ***? | |||

| ***? | ***? | 80 | ***? | ||||

| ***? | ***? | 4300 | ***? | ||||

| ***? | ***? | 110 | ***? | ||||

| ***? | ***? | 1600 | ***? | ||||

| ***? | ***? | 0,75 | ***? | ||||

| ***? | ***? | 45 | ***? | ||||

| ***? | ***? | 180 | ***? | ||||

| ***? | ***? | 7,5 | ***? | ||||

| ***? | ***? | 24000 | ***? | ||||

| ***? | ***? | HSK63 | |||||

| ***? | ***? | 6 | ***? | ||||

| ***? | ***? | 120 | ***? | ||||

| ***? | ***? | 5,5 | ***? | ||||

| ***? | ***? | 244 | ***? | ||||

| ***? | ***? | 0,75 | ***? | ||||

| ***? | ***? | ***? | 6-8 | ***? | |||

| ***? | ***? | 450 | ***? | ||||

| ***? | ***? | 400 | ***? | ||||

| ***? | ***? | 20 | ***? | ||||

| ***? | ***? | 3985 | ***? | ||||

| ***? | ***? | 4000 | ***? | ||||

| ***? | ***? | 96 | ***? | ||||

| ***? | ***? | 6885 | ***? | ||||

| ***? | ***? | 4634 | ***? | ||||

| ***? | ***? | 3362 | ***? | ||||