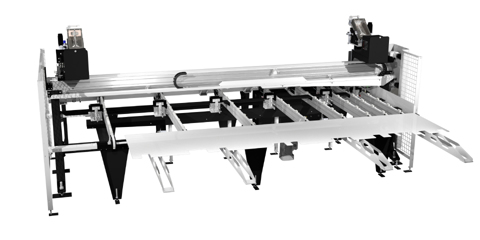

- Robust mechanical structure suitable for high speed

- Axis speeds averaging 125 m/min

- Profile feeding capacity of 9 pieces

- Profile machining length 6500 mm

- Ø 500 mm saw

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Mitsubishi PLC control system

- Service support with remote connection

- Automatic profile recognition system

- Automatic lubrication system

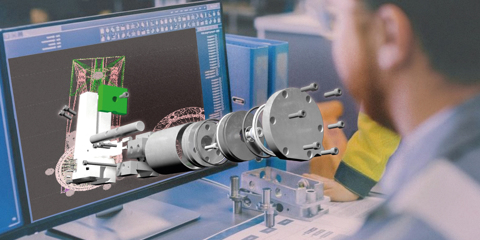

Design

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Ability to perform grooving, hole drilling, marking, cutting at different angles, etc.

- Automatic lubrication system

Control Panel

- 17'' screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Compatibility with 3rd party software

- Data transfer via USB and COM Port

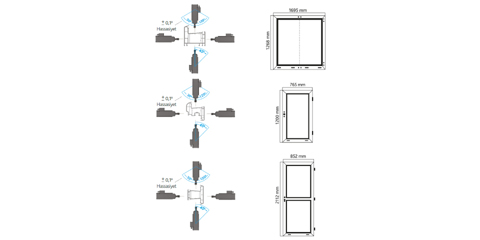

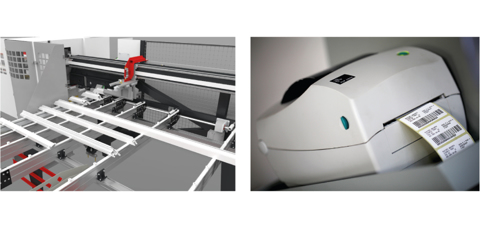

Input Unit

- Strong profile holding structure

- Conveyor system that can carry up to 9 profiles

- Profile transport with a maximum length of 6500 mm and a minimum length of 400 mm

- Automatic profile recognition system

- Linear measuring system

- Infinite length machining option

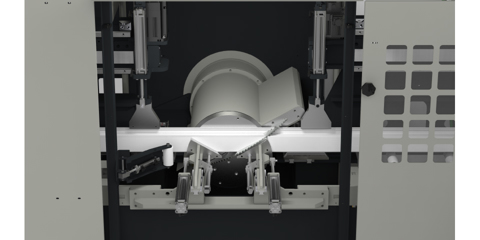

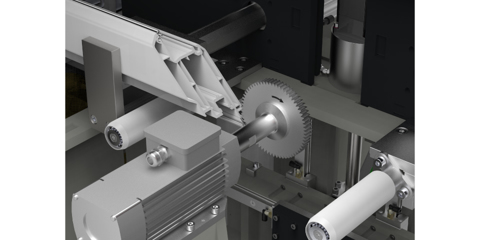

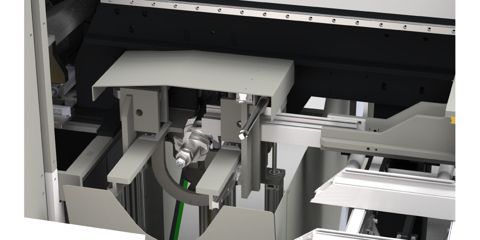

Processing Unit

- 4-axis servo controlled unit

- Tool motors with 4 cutting tools

- Ability to operate two tools simultaneously with high precision

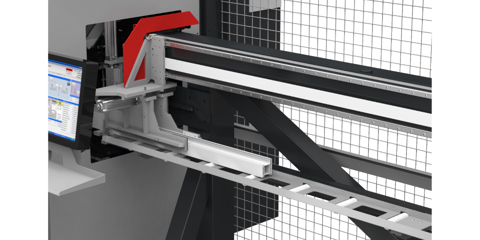

Profile Transfer Unit

Cutting Unit

- Adjustable saw advance speed

- Ø 500 mm saw

Exit Unit

- Profile length up to 4000 mm

- Conveyor where the cut pieces are transferred automatically

- Barcode printer

- Chip conveyor for waste parts

Safety

- Auto-recovery function that sends the tool to the safe zone

|

Description

|

|||||||

| Input Unit | X Axis | Motor power | 1,5 | kW | |||

| X Axis | Axis Speed | 320 | m/min | ||||

| Conveyor | Motor power | 0,55 | kW | ||||

| Conveyor | Axis Speed | 8,8 | m/min | ||||

| Processing Unit | Spindle | Motor power | 4 x 0,75 | kW | |||

| Spindle | Max Rotation Speed | 18000 | rpm | ||||

| X Axis | Motor power | 2 x 0,75 | kW | ||||

| X Axis | Axis Speed | 30 | m/min | ||||

| Y Axis | Motor power | 2 x 0,75 | kW | ||||

| Y Axis | Axis Speed | 30 | m/min | ||||

| Z Axis | Motor power | 2 x 0,75 | kW | ||||

| Z Axis | Axis Speed | 30 | m/min | ||||

| B Axis | Motor power | 0,4 | kW | ||||

| B Axis | Axis Speed | 30 | m/min | ||||

| Transfer Unit | X Axis | Motor power | 1,5 | kW | |||

| X Axis | Axis Speed | 320 | m/min | ||||

| Cutting Unit | Saw | Motor power | 1,5 | kW | |||

| Saw | Max Rotation Speed | 2800 | rpm | ||||

| Saw | Saw Diameter | 500 | mm | ||||

| Y Axis | Motor power | 0,4 | kW | ||||

| Y Axis | Axis Speed | 15 | m/min | ||||

| B Axis | Motor power | 0,4 | kW | ||||

| B Axis | Axis Speed | 400 | °/sec | ||||

| Exit Unit | X Axis | Motor power | 1 | kW | |||

| X Axis | Axis Speed | 320 | m/min | ||||

| Conveyor | Motor power | 0,55 | kW | ||||

| Conveyor | Axis Speed | 8,8 | m/min | ||||

| Waste Conveyor | Motor power | 2 x 0,37 | kW | ||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Consumption | 380 | l/min | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Power | 15 | kW | ||||

| Weight | Net | 5219 | kg | ||||

| Weight | Gross | 6314 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 19108 | mm | ||||

| Machine Dimensions | Width | 4095 | mm | ||||

| Machine Dimensions | Height | 2320 | mm | ||||

PTR 200 Shelf-Type Profile Transport Cart

H 500 Screwing and Drilling Unit

- Fast and automatic screwing of profiles with reinforcement steel at required intervals

- Possibility to drill holes at desired intervals on profiles with reinforcement steel