- Axis speeds averaging 95 m/d

- Profile machining length 4175 mm

- Machinable profile section size 300 x 300 mm

- Number of vices 6 pcs

- Spindle motor 8.5 kW 24,000 rpm

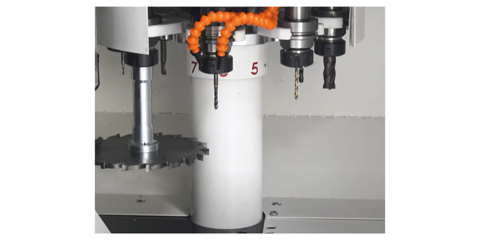

- Number of magazine teams 8 pieces

- Saw Ø 200 mm

- Mitsubishi PLC control unit

- Clamps positioned by the X axis

- Automatic tool recovery in case of power failure

Design

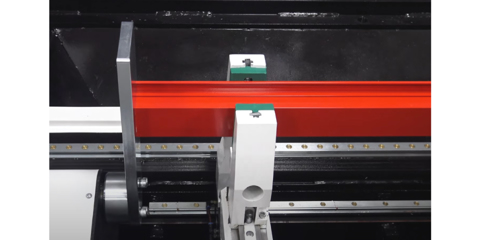

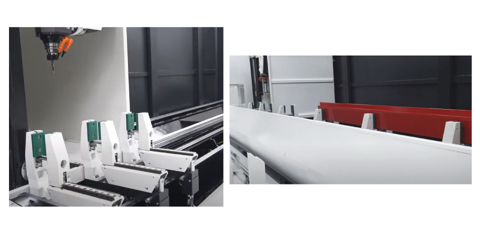

- The absence of any material that can be damaged in areas where chips and chips fall provides a long service life.

- The profile seating surface with a safety cover and roller system that opens and closes in accordance with the ergonomics of use when placing the profile provides convenience to the operator.

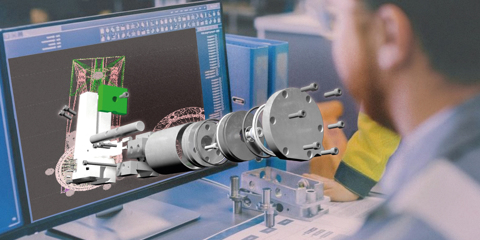

Control Panel

- 19'' screen

- Windows-based, user-friendly Kaban interface with easily adjustable parametric structure

- Compatibility with .NCX extension software

- High performance 4-axis Mitsubishi PLC control unit

- Optical communication and command boost

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

Spindle

- Tool holder

- Encoder

- Temperature control

- Liquid cooling

- Tool cooling

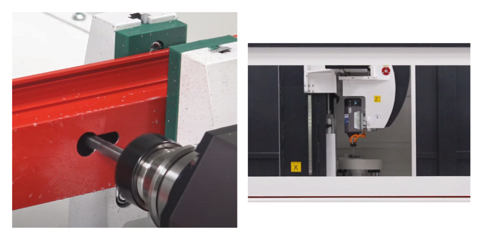

Profile Supports

- Suitable for working with long profiles

Vices

- 6 standard clamps

- Vices positioned by the X-axis

- Profile sliding comfort on the vise surface with the roller system

- Three different clamping forces according to the profile thanks to the pressure regulator

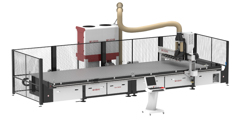

Safety

- Auto-recovery function that sends the spindle to the safe zone

- Working safety with cover and safety barriers

|

Description

|

|||||||

| Magazine Clamp Chip Collection | Motor Power | kW | 3,5 | 3,5 | |||

| Axis Speed | m/min | 135 | 135 | ||||

| Maximum Distance Between The Support Plates | Maximum Machining Length | 4175 | 4170 | ||||

| Motor Power | kW | 0,75 | 0,75 | ||||

| Axis Speed | m/min | 110 | 92 | ||||

| Maximum Length of Machining Parts | mm | 300 | 280 | ||||

| Motor Power | kW | 0,75 | 0,75 | ||||

| Axis Speed | m/min | 45 | 45 | ||||

| Maximum Length of Machining Parts | mm | 300 | 280 | ||||

| Motor Power | kW | 0,75 | 0,75 | ||||

| Axis Speed | º/sec | 90 | 90 | ||||

| Angle | º | 180 | 180 | ||||

| Motor Power | Motor power | 8,5 | 8,5 | ||||

| Maximum Rotation Speed | cycle/min | 24000 | 18000 | ||||

| Number Of Tools | Piece | 8 | 8 | ||||

| Maximum Saw Diameter | mm | 200 | 200 | ||||

| Number of Clamps | Piece | 6 | Piece | ||||

| Machine Dimensions | Pressure | Bar | 6-8 | (6-8) | |||

| Total Air Consumption | Lt/min | 161 | 300 | ||||

| Voltage | V | 400 | 400 | ||||

| Power | kW | 19 | 19 | ||||

| Net Machine Weight | kg | 5670 | 6865 | ||||

| Gross Weight | kg | 6305 | 7500 | ||||

| Length(L) | mm | 7896 | 7680 | ||||

| Width(W) | mm | 3547 | 2500 | ||||

| Height(H) | mm | 2642 | 3000 | ||||

Barcode Reader

Angle Tool Holder

- Thanks to the T tool, it can perform operations on the right and left surfaces of the profile.