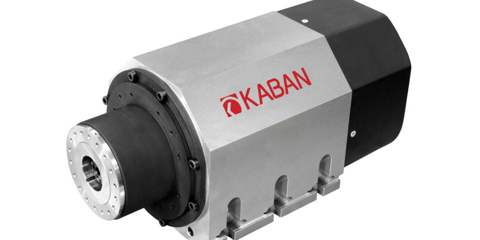

- Spindle motor power: 10-12 kW, 24,000 RPM

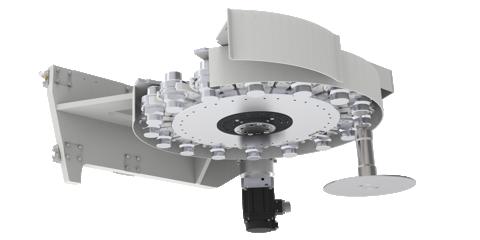

- Magazine with a capacity of 16 tools

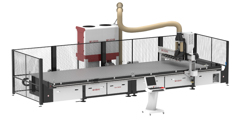

- Double-station profile machining, 2x4900 mm

- Machinable section dimensions: 650 x 350 mm

- Automatic tool length measuring

- Automatic vise positioning

- Average axis speeds of 100 m/min

- Maximum profile processing length 10.300 mm

- Mitsubishi CNC control unit

- Automatic tool recovery in case of a power outage

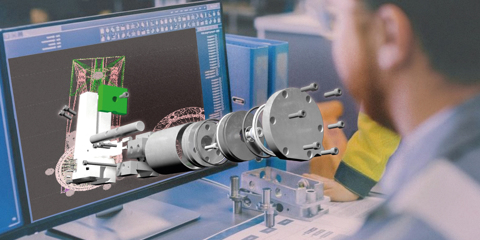

Design

- Consistent precision with stress-relieved cast and welded parts

- Average 100 m/min axis speed

- Ability to perform operations such as milling, notching, drilling, threading, countersinking and cutting

- Double station machining, each 4900 mm long

- Cutting liquid spray system

Control Panel

- 19'' screen

- Windows-based Kaban interface has an easy parametric structure and is user-friendly

- Compatible with .NCX extension softwares

- High performance 4+1 axis Mitsubishi CNC control unit

- Optical communication and command augmentation features

- Option for communication via Ethernet

- G-Code support

- Data transfer via USB and COM Ports

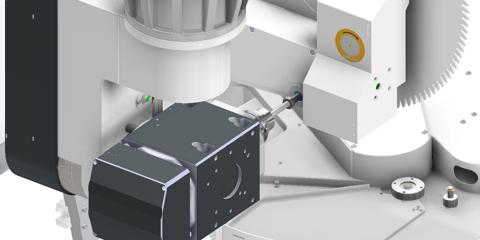

Spindle

- HSK F63 tool chuck

- Encoder

- Temperature control

- Liquid cooling

- Tool cooling

Profile Supports

- Compatible with processing long profiles

Vices

- Standard 10 vises

- Servo-controlled precision automated positioning

- Ease of profile shifting on the vise surface with roller system

- Three different clamping forces adjustable to the profile specifications using a pressure regulator

Safety

- Automatic recovery function that moves the spindle to a safe zone

- Operational safety with protective guards and safety barriers

|

Description

|

|||||||

| Machine Features | X-axis | Motor power | 3,5 | kW | |||

| X-axis | Axis Speed | 136 | m/d | ||||

| X-axis | Part Processing Length | 10300 | mm | ||||

| Y Axis | Motor power | 1,5 | kW | ||||

| Y Axis | Axis Speed | 120 | m/d | ||||

| Y Axis | Workpiece Processing Width | 650 | mm | ||||

| Z Axis | Motor power | 1 | kW | ||||

| Z Axis | Axis Speed | 40 | m/d | ||||

| Z Axis | Machining Height | 350 | mm | ||||

| A Axis | Motor power | 0,75 | kW | ||||

| A Axis | Axis Speed | 146 | º/sec | ||||

| A Axis | Angle | ±110 | º | ||||

| C Axis | Motor power | 0,75 | kW | ||||

| C Axis | Axis Speed | 146 | º/sec | ||||

| C Axis | Angle | ±180 | º | ||||

| spindle | Motor power | 10-12 | kW | ||||

| Spindle | Maximum Rotation Speed | 24000 | d/d | ||||

| tool magazine | Number of Tools | 16 | Piece | ||||

| magazine (Tool chuck) | Maximum Saw Diameter | 200 | mm | ||||

| Saw | Diameter | 500 | mm | ||||

| Vise | Axis Speed | 15 | m/d | ||||

| Vise | Number of Vises | 10 | Piece | ||||

| Technical Specifications | Weather | Pressure | 6-8 | Bar | |||

| Weather | Total Air Consumption | 350 | l/d | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Strength | 24 | kW | ||||

| Weight | Net | 17157 | kg | ||||

| Weight | Gross | 17390 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 14728 | mm | ||||

| Machine Dimensions | Width | 4341 | mm | ||||

| Machine Dimensions | Height | 2834 | mm | ||||